The challenges that Canadian supply chain companies face are mounting. And while overseeing the import and transportation of goods has never been more demanding, remaining efficient while reducing operational costs is still every logistics manager’s goal – no matter which industry they serve.

However, meeting that goal is highly dependent on overcoming six major logistics-related challenges that every Canadian logistics provider is facing:

1. Unexpected Weather

Unpredictable and frequently changing weather can be a huge threat to Canadian supply chains – especially when it comes to maintaining smooth operations. All too often, Canadian winters bring inconsistent conditions, and when spontaneous snowstorms erupt, the safe and speedy delivery of products can be greatly disrupted.

Understanding and tracking how inclement storms will impact production is therefore critically important for companies that want to maintain productivity in bouts of extreme weather. Below are a few tips to consider:

Weather Tracking

An experienced logistics company knows to stay up-to-date on weather forecasts – especially in the areas that cover the routes their shipments will soon be taking. By trusting a logistics business that anticipates challenges as early as possible, sellers can rest assured that their products will be delivered to their destination on time, regardless of the weather.

Contingency Plans

When planning shipping routes, logistics companies need to establish contingency or ‘back-up’ plans – in case of emergency or troubling weather. Adaptability is key in maintaining optimal delivery time and service.

2. Environmental Regulations

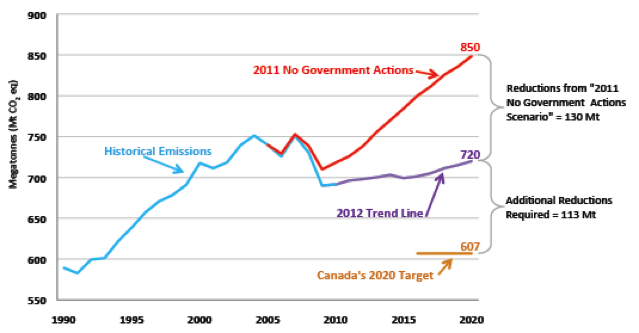

According to Environment and Climate Change Canada, Canada’s goal is to reduce its greenhouse gas emissions by 130 megatonnes by 2020. How does the government plan to do this?For the most part, by incentivizing big businesses (who contribute heavily to these emissions) to adapt and reduce their carbon footprints.

Canadian Manufacturers & Exporters reports that 50% of an average company’s carbon dioxide emissions occur in the supply chain.

It is, therefore, no surprise that the Canadian government has increasing ambition to significantly cut the country’s total emissions:

Canada’s Historical Greenhouse Gas Emissions and Projections to 2020

Source: Reducing Canada’s greenhouse gas emissions

With increasing expectations from international climate committees, the pressure is on for big businesses to be environmentally conscious. Therefore, it is a critical timefor supply chain businesses like McKenna to get involved in the movement, helping to preserve the environment and to push for improved practices.

3. Globalization

According to the World Trade Organization, global business trading has grown at an annual rate of 2.1% – 4% in 2018. However, going global is no easy task:

Importing & Exporting Across Borders

As there is more room for error when you have less visibility over your supply, it is critical that businesses looking to go overseas cover all of their bases when making a move from national to international. For example, what is legal and common practice here in Canada may not be legal and common practice elsewhere, including import-related restrictions.

Did you know that Canada has strict rules about importing energy-related goods, dangerous goods, and even cultural items? You can check out the specific regulations for importing these types of goods into Canada by visiting Canada’s Import Permits and Restrictions page.

Another concern is the rising tariffs coming out of the U.S.A. The Retail Council of Canada has warned Canadians about additional costs for yogurt, pizza, paper, lawn movers, orange juice, soups, chocolate, and more. To learn more about these new tariffs, please see CTV News’ ‘List of U.S. Goods Being Hit With Canadian Counter-Tariffs’.

Geography

Geography is also an important thing to consider when it comes to globalization. For example, Canada does not experience many earthquakes, so the likelihood of transportation being disrupted by one is low. However, in countries such as Japan, precautions must be developed to ensure smooth shipments during commonly occurring earthquakes.

International Currencies & Treaties

As a logistics provider, it is also critical to understand the conversions between different international currencies, as well as to be aware of securities and border treaties – as each of these factors can impact shipping.

4. Unpredictable Fuel Price Hikes

In Canada, fuel costs rise and fall for a number of reasons. For example, the Trans Mountain Pipeline dispute, although entirely unrelated to logistics, has recently caused a huge spike in fuel prices in British Columbia.

The following chart shows just how much fuel prices fluctuated in Vancouver in 2017:

Source: Kent Group Ltd.

How does fuel impact logistics? When the price of fuel increases, companies that run on “gas-guzzling” transportation are forced to allocate more of their budget to powering supply chain vehicles. When other sections of a company suffer because of budget reallocations, businesses can face a variety of problems – including wage cuts or de-funding of other programs.

Increases in fuel prices also pressure companies to begin charging more for their products and services – damaging and even ending relationships with customers who are unwilling or unable to pay more. When goods aren’t being bought and shipped, the entire economy suffers – another reason that companies might benefit from “going green”.

At McKenna, expert logistics managers investigate fuel prices to ensure their routes are not only as environmentally friendly as possible, but as efficient as possible – reducing overhead costs and emissions. Also, McKenna actively prepares for fluctuating fuel prices – to protect their customers from facing huge spikes in charges, and to protect their employees from being laid off (when fuel costs are high).

5. Big Data

In a tech-driven world, data and analytics play a huge role in making supply chain operations more efficient. Real-time analytics have revolutionized the logistics industry as customers pushed (and continue to push) for more involvement in tracking their purchases.

However, while data tracking has its benefits, it has also made supply chain systems more complex. For example, shippers and receivers must now constantly track and enter data, updating the exact location of freights. Also, training employees to do this, and purchasing new equipment and systems with these capabilities, can be costly.

At McKenna, crews leverage innovative technology to not only track, organize, and store data, but to also protect the privacy of buyers and sellers. While this technology can be costly, the satisfaction of clients and customers should always come first.

6. Finding the Right Talent

It can be very difficult to find supply chain managers with the competency to keep things running smoothly at all times. Companies need supply chain managers with a good understanding of their business and well as the different processes that govern their supply chains.

Companies also have to maintain good relationships with suppliers and partners as more and more companies are turning to private labelling (purchasing goods from other companies and rebranding them for sale). Without these interpersonal skills, and the ability to adapt to the processes of other companies, supply chain managers are bound to fail.

To attract and retain high-quality talent, McKenna works hard to support a family-oriented, skill-developing environment that the McKenna team truly enjoys working in. In fact, it is engrained in our values to treat employees with respect for their craft as well as to provide individuals with the benefits and support they deserve.

How Do You Deal With These Supply Chain Issues?

More and more, companies are outsourcing their logistics as management becomes too much for them to handle themselves. If you have determined that, it may be time to consult a third-party logistics provider like McKenna. Contact us today to unlock the following added benefits:

- Flexible pricing and accommodations during busy seasons

- Efficiency is optimized by tried and true picking and packaging systems and procedures

- Save money by not having to own your own warehouse or having to pay/hire employees

To learn more about how we can offer the right shipping solutions for your business, please have a look at ‘Our Approach to Logistics’.

Through competitive advantages, KPIs, and leadership, we’re your best choice when it comes to increasing the packaging and shipping productivity of your company.

Call us at 1-800-561-4997 or send an email to sales@mckennalogistics.com to get started today!